משאבות תעשייתיות ALLWEILER

חברת רדקו מייבאת ומשווקת משאבות מתוצרת חברת ALLWEILER אשר הינה חלק מקבוצת CIRCOR.

חברת CIRCOR הינה חברת האם של החברות הבאות:

ALLWEILER, HOUTTUIN, IMO, TUSHACO, WARREN, ZENITH

חברת ALLWEILER הינה מהמובילות בתחום טכנולוגיות שאיבה ברמה עולמית.

חברת רדקו מייבאת את מוצרי אללווילר ביבוא מקביל

יצרנית המשאבות הגרמנית הוותיקה ביותר, שנוסדה בשנת 1860,

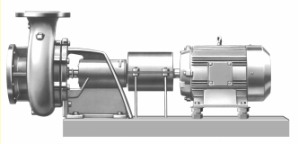

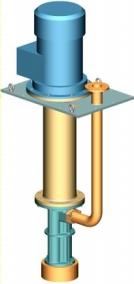

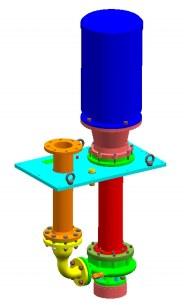

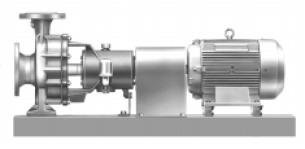

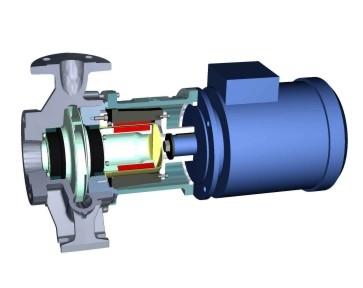

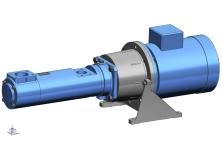

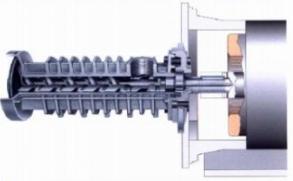

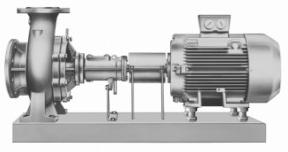

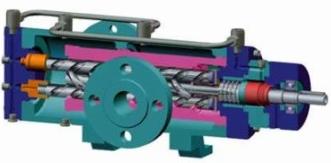

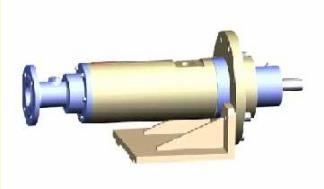

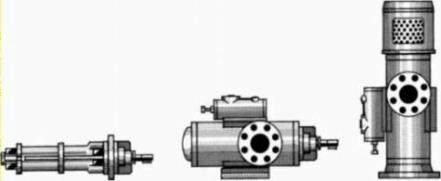

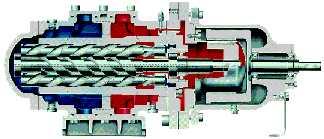

Allweiler GmbH הינה מהחברות המובילות בשוק האירופי בטכנולוגיות ובפתרונות לטיפול בנוזלים לבניית ספינות, ייצור חשמל ויישומים תעשייתיים מיוחדים. מגוון המוצרים שלה הוא ללא תחרות בענף וכולל משאבות צנטריפוגליות, מדחף, בורגיות, פריסטלטיות, פרופלור, דלק, רב דרגתיות ועוד.

כחבר ב- CIRCOR, ל- Allweiler GmbH יש גישה למשאבי כספים וייצור משמעותיים. כל משאבי המחקר והפיתוח של הקבוצה, יכולות הייצור ואנשי המכירות והשירות זמינים ברחבי העולם.

משאבות ALLWEILER נמצאות בשימוש:

אוניות, מתקנים ימיים, תחנות כוח, תעשיית השמנים, הגז והדלק,

מערכות מים , השקייה, טיהור , שאיבה מבארות, תעשייה כימית, העברת חום,

מכונות כלים, תעשיית בניה, תעשיית הקרטון והנייר, תרופות, מזון.

עמידה בתקנים בינלאומיים.